IMP.A.C. 22 ASA

Special automatic self-adjusting palletizer with stationary pallet

Max Production: 600 cartons/h

CONTACT US

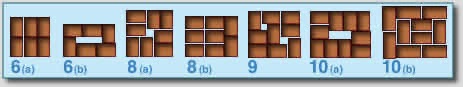

The IMP.A.C. 22 ASA is a “SPECIAL” machine because it is used in particular applications where the production line can produce an unlimited number of different formats with the most varied dimensions from a minimum of 300x150xH = 25 mm to a max. of 2400x1200xH = 400 mm and a production capacity that can reach 600 cartons/h. This specific palletizer is widely used in the furniture industry sector, packaged or in KIT. The cardboard coming from an upstream line is oriented according to the predisposed formation and sent into the layer pre-forming area. The layer thus composed is transferred onto a platform equipped with vertical and horizontal movements, the first for searching and positioning the layer unloading, the second for transferring the layer onto the stationary pallet. The cycle will repeat itself until the completion of the pallet which will be evacuated and replaced, to start a new cycle. All the synchronisms of the movements are coordinated by a programmable modular system (PLC). The machine can be programmed to palletize cartons of different sizes, formations and number of layers.

Min. 200 x 150 x h. 25

Min. 1000 x 800 x h. 100

– components and compliance with ATEX standards

– thick painting with special paints

– machine structure entirely in stainless steel

– anti-corrosion components

– wider or taller machine for pallets with non-standard dimensions

– flap positioning device between the layers

– palletization on moplen plastic sheet

– automatic press adjustment

– remote teleservice module