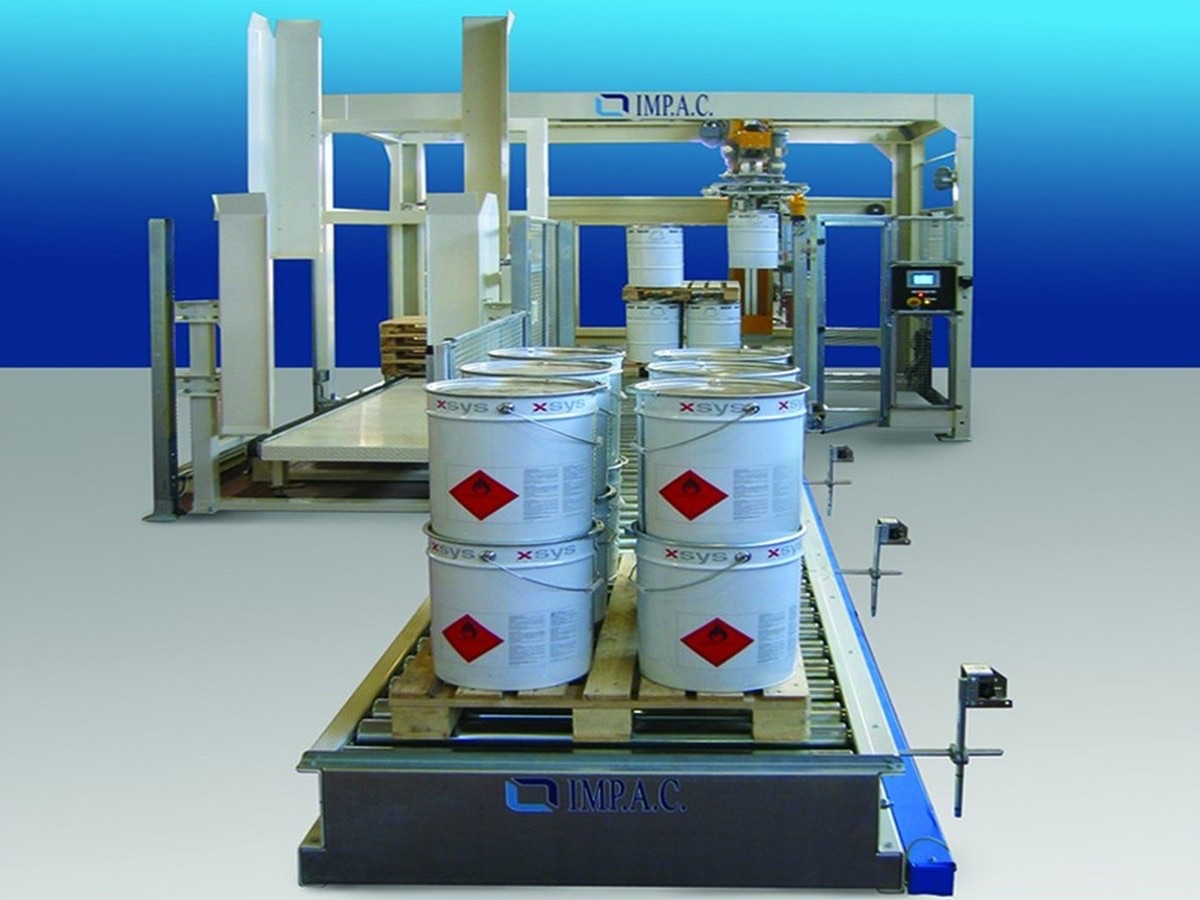

IMP.A.C. ROBOTEX 526 A

Cartesian robot for palletizing Pails with roller conveyors (also available in multi-pallet version)

Max Production: 300 Pails-Jerrycans/h basic solution

500 Pails-Jerrycans/h speed solution

The IMP.A.C. ROBOTEX 526 A is completely automatic, complete with handling roller conveyors for empty and full pallets. It is a machine suitable for being inserted at the end of the line of fully automatic production plants where the presence of the operator is not required, for a maximum production of 500 pails/h. The bucket coming from an upstream line is then sent to a positioning station to be picked up by the gripper. The cycle will repeat itself until the pallet is completed, which will be evacuated and replaced to start a new cycle. The movement system is based on Cartesian axes and the positioning is controlled by an encoder. All the synchronisms of the movements are coordinated by a programmable modular system (PLC). The machine can be programmed to palletise buckets of different sizes, formations and number of layers.

Min. diameter 200x h 180

– components and compliance with ATEX standards

– thick painting with special paints

– machine structure entirely in stainless steel

– anti-corrosion components

– wider or taller machine for pallets with non-standard dimensions

– flap positioning device between the layers

– palletization on moplen plastic sheet

– automatic press adjustment

– remote teleservice module