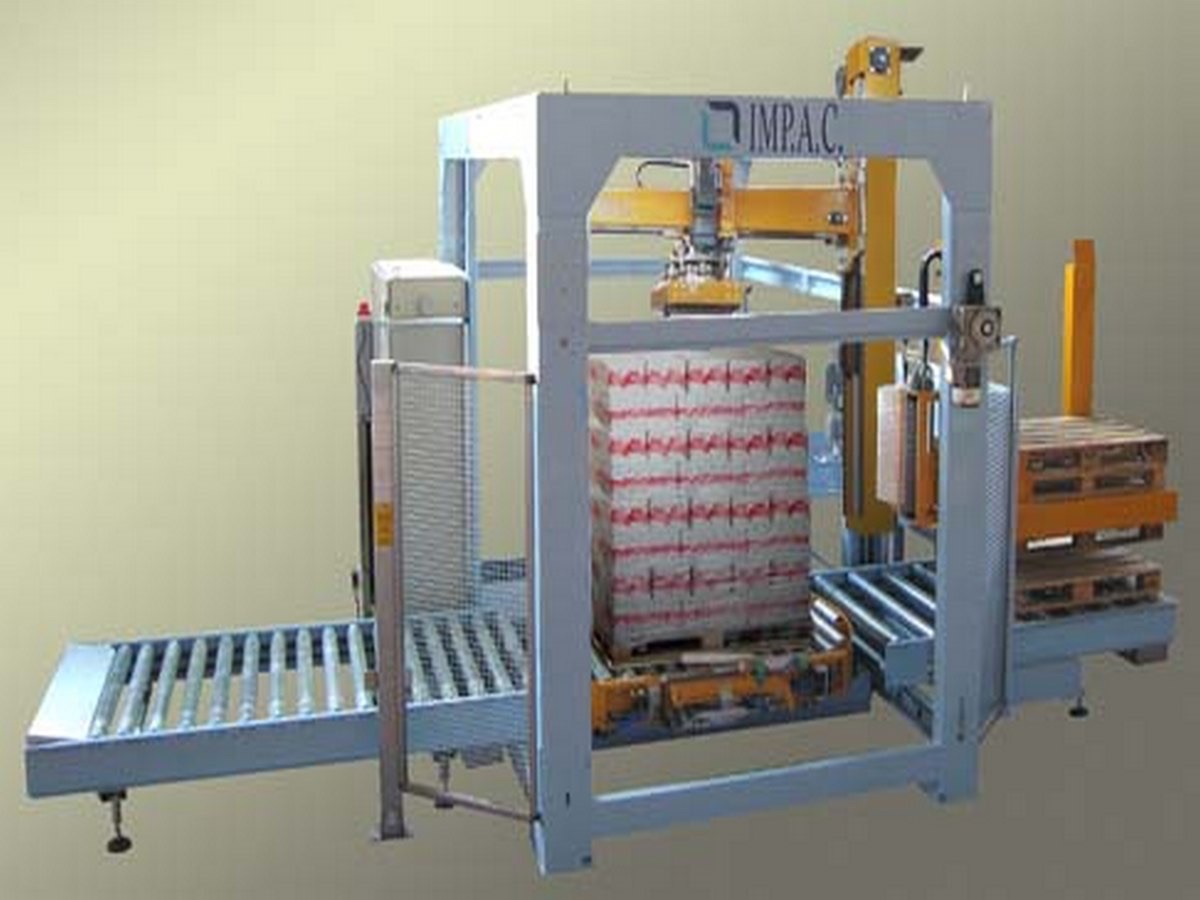

IMP.A.C. ROBOTEX 226 APR

Cartesian robot for palletizing bundles with built-in automatic rewinder

Max Production: 270 cartons-bundles/h basic solution

450 cartons-bundles/h speed solution

The IMP.A.C. ROBOTEX 226 APR is an innovative fully automatic machine, complete with roller conveyors for moving empty and full pallets. This palletizer has been studied and designed to solve problems common to many users and precisely: 1. possibility of palletizing all types of bundles (10-15 kg) and cartons with different sizes and weights, using the same equipment. 2. Possibility of palletizing and wrapping the pallet at the same time giving stability to the load and therefore the possibility of palletizing unstable and slippery bags. 3. Possibility of installing this palletizer in limited spaces as the overall dimensions are very small. It is a machine suitable for being inserted at the end of the line of fully automatic production plants where the presence of the operator is not required, for a maximum production of 450 packs-cartons / h. The bag gripping system with total wrapping gripper assumes great importance, which allows the handling of any type of bag (paper, jute, plastic, valve, sewn or electro-welded), in particular for difficult bags, for example half-empty bags. o bags containing products at the limit of viscosity (water), complete with the device for pressing the bag on the pallet. The bag coming from an upstream line is pressed to be made uniform and compact and then sent to a positioning station to be picked up by the bag gripper. The ready bag is picked up, oriented, positioned and pressed on the pallet according to the set program. The cycle will repeat itself until the pallet is completed, which will be evacuated and replaced to start a new cycle. The movement system is based on Cartesian axes and the positioning is controlled by an encoder. All the synchronisms of the movements are coordinated by a programmable modular system (PLC). The machine can be programmed to palletize bags of different sizes, formations and number of layers.

Min. 300 x 200 x h. 80 mm

Min. 800 x 600 x h. 100 mm

– components and compliance with ATEX standards

– thick painting with special paints

– machine structure entirely in stainless steel

– anti-corrosion components

– wider or taller machine for pallets with non-standard dimensions

– flap positioning device between the layers

– palletization on moplen plastic sheet

– automatic press adjustment

– remote teleservice module