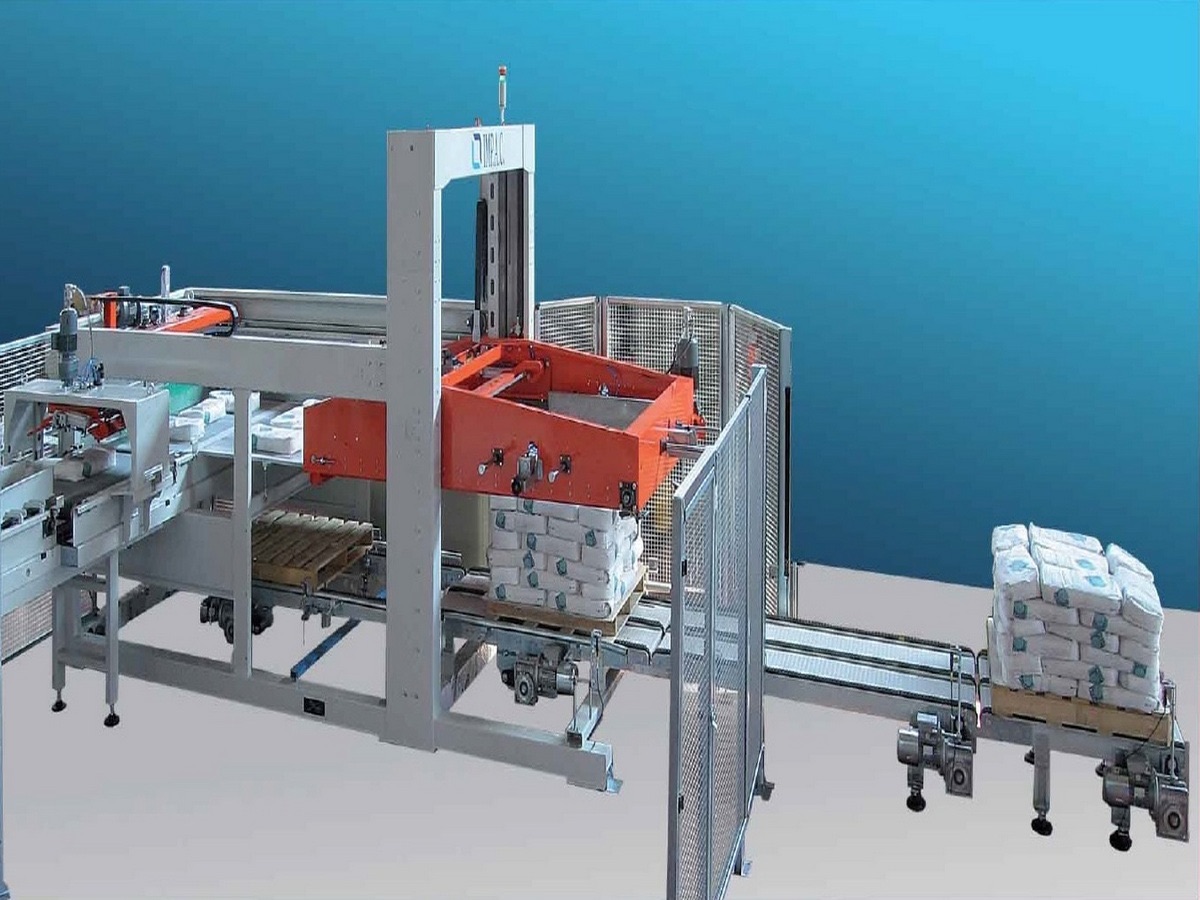

The palletizer IMP.A.C. 12 AL, completely automatic, is indicated for all the activities with outputs up to 700 bags/h. The bag, coming from an upstream line, is pressed to become even and compact, then it’s oriented following the preset formation and directed to the preforming zone. The composed layer is transferred on a vertically and horizontally moving platform, the first one for the search and the positioning of the layer unloading, the second one for the transferring of the layer on the firm pallet. The cycle will repeat itself until the finishing of the pallet that will be emptied and replaced, to begin a new cycle. All the movements synchronisms are coordinated by a programmable modular system (PLC). The machine can be programmed to palletise bags of different dimensions, formations and layers number.

Min. 400 x 300 x h. 80 mm

Min. 1000 x 800 x h. 100 mm

– components and compliance with ATEX standards

– thick painting with special paints

– machine structure entirely in stainless steel

– anti-corrosion components

– wider or taller machine for pallets with non-standard dimensions

– flap positioning device between layers

– palletization on moplen plastic sheet

– automatic press adjustment

– remote teleservice module