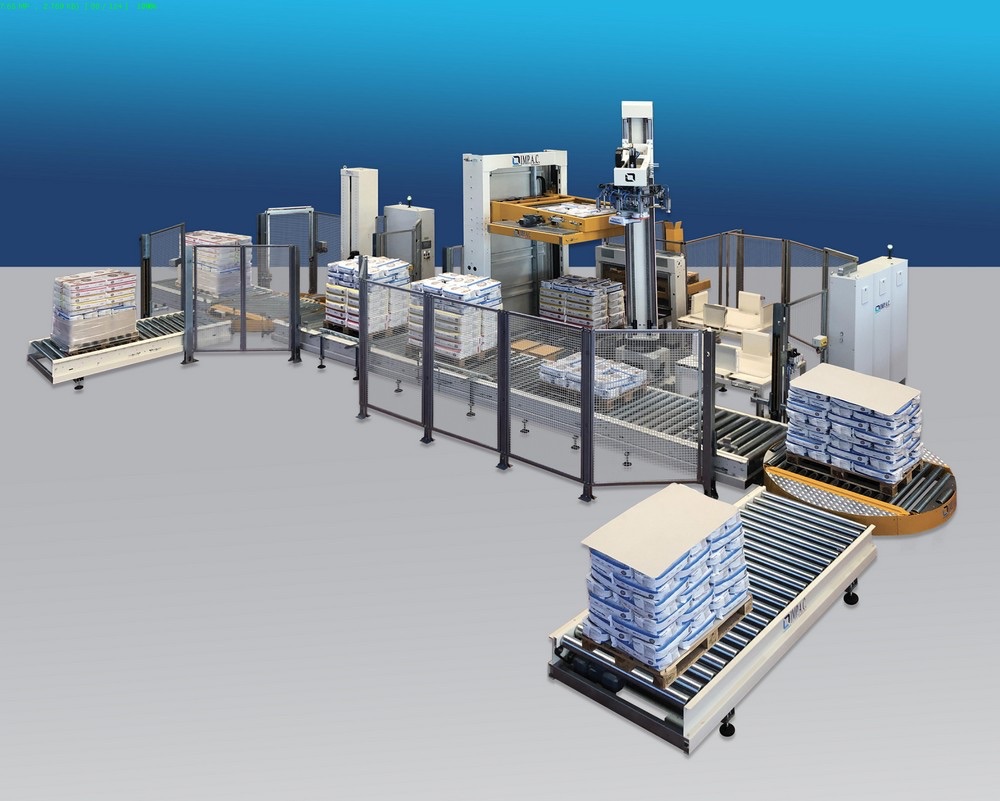

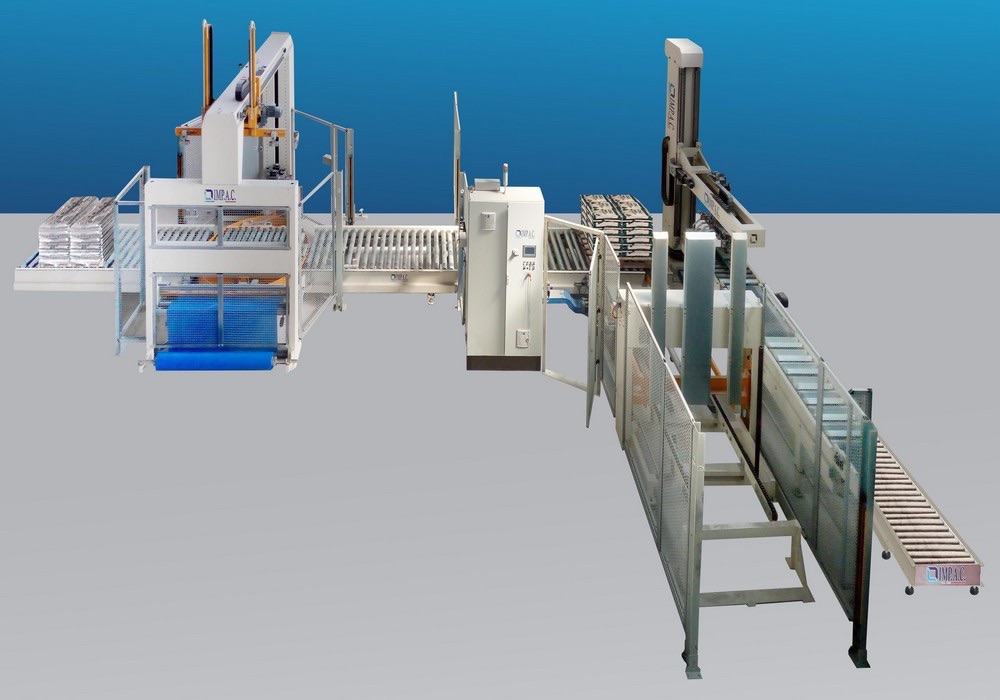

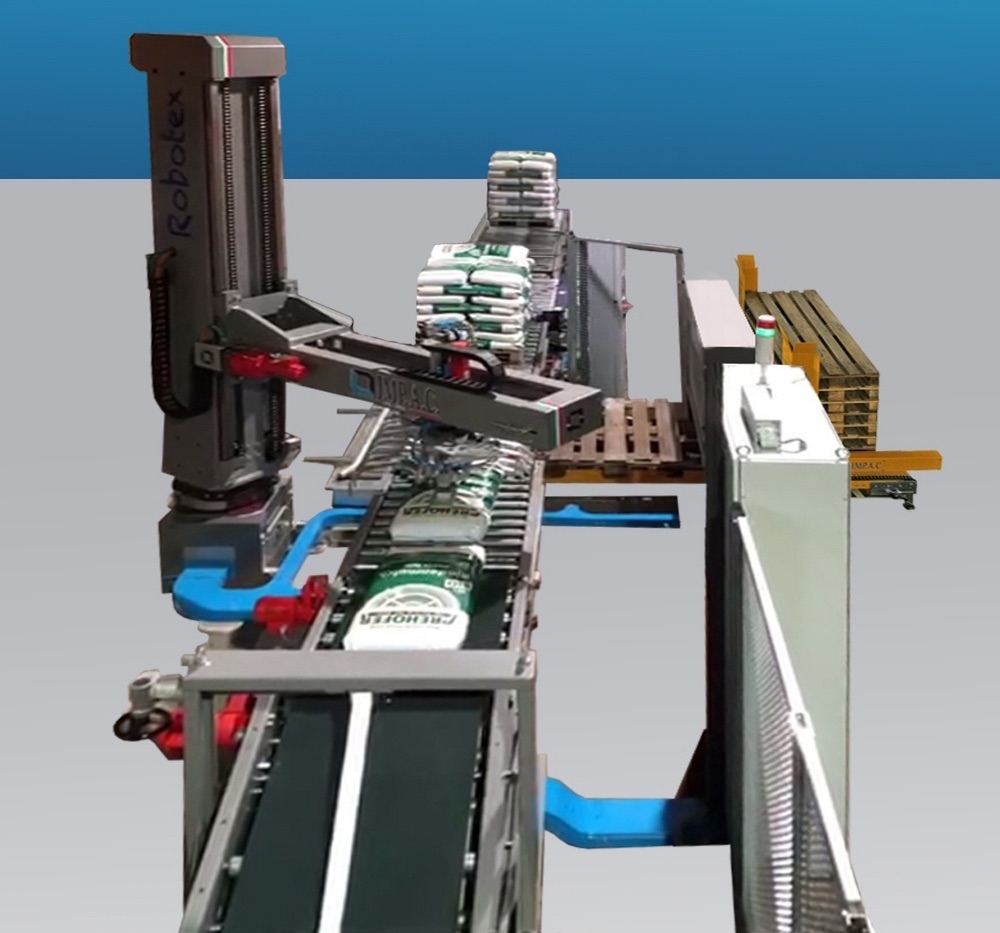

IMP.A.C. ROBOTEX 127 A

Robotic bags palletizer with rotating column

Max Production: 650 bags/h

CONTACT US

The ROBOTEX IMP.A.C. 127 A has a max output of 650 bags/h. The key part of the machine is the pliers that take the bags. This pliers totally encloses the bag, enabling the operation with each kind of bag ( paper, jute, plastic, valve, sewn bags, electro welded bags) even with the most difficult bags, like half-empty ones, bags filled with very low viscosity products (water). The pliers are completed with integrated bag pressing device. The bag, coming from an upstream line, is pressed to become even and compact, then it goes to a station, to be picked up and transferred on the pallet. The ROBOTEX IMP.A.C. 127 A is constituted by a mechanical mobile hand capable of rotary and linear movement and adaptable to each kind of bag. The whole is assembled on an arm with vertical and rotating movement as to the central axe of the machine. We have created total mobility condition in each direction. All the movements synchronisms are coordinated by a programmable modular system (PLC). The machine can be programmed to palletise bags of different dimensions, formations and layers number.

Min. 500 x 300 x h. 80 mm

Min. 1000 x 800 mm

– components and compliance with ATEX standards

– thick painting with special paints

– machine structure entirely in stainless steel

– anti-corrosion components

– wider or taller machine for pallets with no-standard dimensions

– flap positioning device between layers

– palletization on moplen plastic sheet

– automatic press adjustment

– remote teleservice module